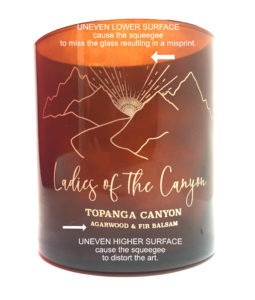

Screen Printing on Glass & Uneven Surfaces

Screen printing on glass continues to play a significant role in the production of glass products for industrial and consumer applications. Unfortunately, Glass decorators in screen printing face challenges on objects of uneven surfaces or textures.

See Photos Below:

Artwork Disclaimer & Process Printing: Upon your approval, you agree to this disclaimer prior to print. Approving this proof means you understand that laser, inkjet, jpeg or pdf/digital proofs etc., do not accurately represent final print quality, and are purely for rough visual/copy approval purposes only. Please know, we print on a variety of substrates and colored substrates i.e. glass, tin, and plastic. The same ink will look different on a white tin versus clear glass. Even the same color printed on white paper will look slightly different printed on a white tin due to the reflective qualities of the tin. Clients must understand that when printing CMYK it is very difficult to achieve an exact PMS match. We diligently strive to achieve exact matches whenever possible, but sometimes this is just not possible due to the color of the product or the substrates we’re printing on.

If you have a client who is adamant about exact PMS matches, we suggest a pre-pro sample for $60.00. It is important for you and your customers to understand that no matter how hard we try, PMS colors rarely look like the computer screen or the same as if they were printed on white paper. Also, the process of some colors, gradients or mesh effects simply cannot be exactly reproduced using Full Color Inkjet Spray Ink, Silkscreen or Pad Print due to how the commercial printer reads the artwork file in the CMYK process. In addition, some shifting may occur to the artwork registration during this process.

Process Printing & Trade printing (In addition to our Artwork Disclaimer & Process Printing):

We have been printing on tins and glass for 25 years, our Printing Process is handcrafted silk-screened and pad printed where each product is manually placed on the mold for printing one at a time. This is not a 100% perfect process and We try our best to match the proof. For any request that demands a perfect aligned imprint or must be exact color, we are happy to decline our service to you or your client.

We have been printing on tins and glass for 25 years, our Printing Process is handcrafted silk-screened and pad printed where each product is manually placed on the mold for printing one at a time. This is not a 100% perfect process and We try our best to match the proof. For any request that demands a perfect aligned imprint or must be exact color, we are happy to decline our service to you or your client.

Therefore, we require an additional 3% of product overs to cover any damages or defects when handling your products. If 3% cannot be provided, pricing will be increased to accommodate for exact quantities. Claims for defects, damages, or shortages must be made in writing no later than 5 calendar days after delivery. If no such claim is made, the provider and customer understand that the job has been accepted. By accepting the job, the customer acknowledges that the provider’s performance has fully satisfied all terms, conditions, and specifications. Provider warrants that the work is as described in the purchase order. The customer understands that all sketches, copy, dummies, and preparatory work shown to the customer are intended only to illustrate the general type and quality of the work. They are not intended to represent the actual work performed. The provider warrants only that the work will conform to the description contained in the purchase order. The provider’s maximum liability, whether by negligence, contract, or otherwise, will not exceed the return of the amount invoiced for the work in dispute. Under no circumstances will the provider be liable for specific, individual, or consequential damages.